Durometers

-

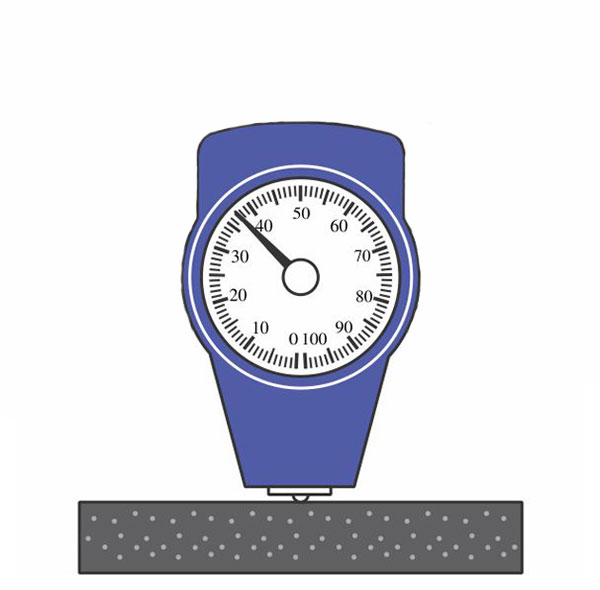

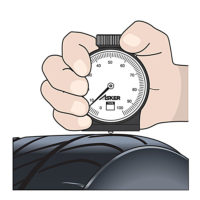

Handheld Durometer

-

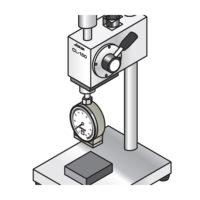

Constant Load Stand Durometer

-

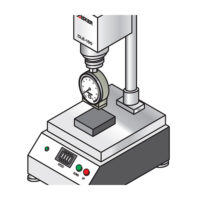

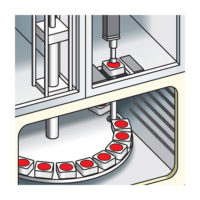

Auto Load Durometer

-

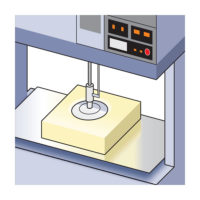

Auto Foam Hardness Tester

-

Temperature Controlled Durometer

Hoto Instruments is devoted to providing accurate measuring instruments for each and every need. One of our most popular instruments is the durometer. Durometers are vital to the manufacturing industry because of their usefulness in determining the hardness of rubber and plastic materials. Durometers test the range from foam rubber to hard plastics by measuring the resistance to indentation of these rubbers, polymers, and elastomers.

Manufacturers require consistency and precision in their quality control testing, which our durometers deliver. A few instances of products that durometers test during manufacturing are: inline skates, truck tires, shoe inserts, and o-rings. These products all require exactness and consistency in manufacturing to fulfill their functions.

The term “durometer” is also used to denote the material’s rating on a hardness scale. The higher the number, the harder (or capacity to resist indentation), the material is. For instance, inline hockey skate wheels have a lower durometer rating, around 72-74A durometers for more hold and responsiveness to fast shifts in direction, versus sporting skates that are 82-84A durometers for faster speeds.

There are a variety of scales that are used to test the range of hardness. Shore A, Shore D, and Asker C are some of the most common scales. Durometers, often referred to as “Shore durometers” are named after the man who invented the system to measure hardness, Albert Ferdinand Shore.

Depending on the application a durometer may be used to test samples by hand or with a constant load stand that eliminates speed and load variables. Auto loading durometers are also available from Hoto Instruments to eliminate those variables and automatically test rubber or plastic samples.

Manufacturers require consistency and precision in their quality control testing, which our durometers deliver. A few instances of products that durometers test during manufacturing are: inline skates, truck tires, shoe inserts, and o-rings. These products all require exactness and consistency in manufacturing to fulfill their functions.

The term “durometer” is also used to denote the material’s rating on a hardness scale. The higher the number, the harder (or capacity to resist indentation), the material is. For instance, inline hockey skate wheels have a lower durometer rating, around 72-74A durometers for more hold and responsiveness to fast shifts in direction, versus sporting skates that are 82-84A durometers for faster speeds.

There are a variety of scales that are used to test the range of hardness. Shore A, Shore D, and Asker C are some of the most common scales. Durometers, often referred to as “Shore durometers” are named after the man who invented the system to measure hardness, Albert Ferdinand Shore.

Depending on the application a durometer may be used to test samples by hand or with a constant load stand that eliminates speed and load variables. Auto loading durometers are also available from Hoto Instruments to eliminate those variables and automatically test rubber or plastic samples.

WHAT IS A DUROMETER?

A durometer is a device used to measure the hardness of a wide variety of materials, from soft rubbers and polymers to hard plastics. Hardness measurements are used for quality control or comparison purposes. Durometers with varying levels of sophistication and accuracy may be used depending upon the application.

Read More…

Read More…