DI-12 Motorized Breakaway Torque Auditing

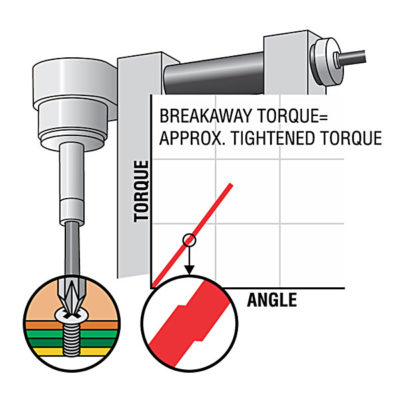

There’s a gap between “applied torque” and “actual tightening torque” when using power tools. Dynamic torque applied to fasteners is affected by different variables, making torque auditing extremely important in deriving “actual tightening torque” on a case-by-case basis.

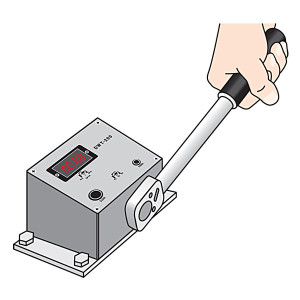

Breakaway tests are often used to detect actual tightened torque at the point fasteners begin to move. Plastic and small fasteners are challenging to audit in this way and may fail to show a clear dip in torque. Additionally, it takes a skilled operator to perform a breakaway test.

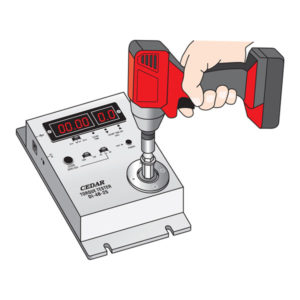

Imada’s DI-12 motorized auto-detect breakaway torque tester drives the test piece at consistent speed and detects breakaway torque of even small or plastic fasteners. The DI-12 can also detect yield torque value for a specific joint, to easily establish ideal tightening torque.

Operation Modes

The tester features three measurement modes: TR, PP and PD. TR displays real time torque values. PP Displays peak torque values. PD determines breakway and yield torque (CW only). If breakaway torque value is detected, the green indicator will light, and tester rotation will stop automatically. The DI-12 outputs torque data continuously (in PD mode) to data acquisition software via the USB virtual COM port, enabling the display of breakaway torque profiles.

What’s Included?

All testers come with a 3-Point Certificate traceable to NIST. ISO-17025 Certificates are available at an additional charge. All testers are sold in a complete kit with tester, hard plastic carrying case, and AC adapter/charger.The DI-12 can run on internal rechargeable batteries or the AC adapter/charger.