- High performance and accuracy

- Calibration cert traceable to NIST included

- Optional ISO-17025 calibration available

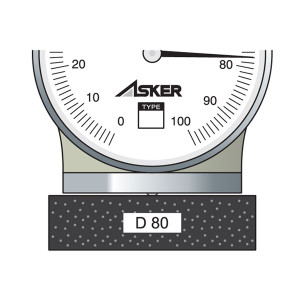

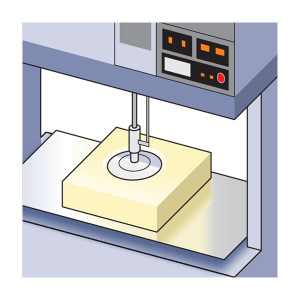

The Asker Model X Durometer is a precision instrument for measuring the hardness of various types of rubbers and plastics. Durable metal cases are rugged enough for a production environment. X handheld durometers are easy to use. The easy operation allows for rapid testing with repeatable results. The Asker High Performance X series has an accuracy of ±.75 point and is available in Type F for soft materials like sponge rubber and urethane foam. X Model durometers are available in ASTM D 2240 Types: Shore A Hardness, Shore D Hardness, Asker C Hardness, as well as Asker F Hardness. Type F hardness testers use their own weight to determine hardness.

Add ‘P’ to the model number to specify optional peak indicator, for example XP-A. Add ‘L’ to the model number to specify extended presser foot models.

Operation

As the X durometer is pressed against the sample, the material resistance force and indentor spring load balance. The depth of the indentor is measured, which provides a measure of the material’s hardness. Values are based upon a 100 point scale (accuracy ±.75 point). However, as time elapses the indicator will “creep” back so that a reading taken a few seconds after the indentor makes contact with the sample will be less than the peak reading. Asker durometers offer a peak indicator as an option to more closely monitor the difference between peak and “creep”.

What’s Included with the Durometer?

X durometers are sold as kits. All new durometer purchases include: durometer, hard plastic carrying case and 3-Point Calibration certificate traceable to NIST.